I will start this post with a short personal story about how I got into electronic packaging and specifically, rheology in electronic packaging. When I was a fourth year graduate student at Northwestern I started looking for a job at the typical places an industrial polymer rheologist might consider, like Dow, DuPont, GE Plastics and others. My thesis advisor, Prof. William Graessley asked me if I had sent my resume to IBM. I was puzzled and asked him why I should consider IBM. He told me IBM did a lot of very interesting and sophisticated work in polymers. I sent my resume to IBM Ph.D. recruiting and I got seven calls from various IBM locations. Turns out, rheology was very important to many applications within IBM. After several interviews I accepted a position at IBM in Endicott, NY which was a big technical hub for electronic packaging. The rest they say is history!

I will start this post with a short personal story about how I got into electronic packaging and specifically, rheology in electronic packaging. When I was a fourth year graduate student at Northwestern I started looking for a job at the typical places an industrial polymer rheologist might consider, like Dow, DuPont, GE Plastics and others. My thesis advisor, Prof. William Graessley asked me if I had sent my resume to IBM. I was puzzled and asked him why I should consider IBM. He told me IBM did a lot of very interesting and sophisticated work in polymers. I sent my resume to IBM Ph.D. recruiting and I got seven calls from various IBM locations. Turns out, rheology was very important to many applications within IBM. After several interviews I accepted a position at IBM in Endicott, NY which was a big technical hub for electronic packaging. The rest they say is history!

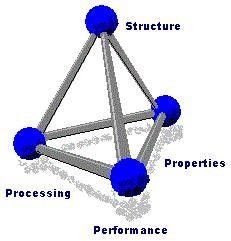

We are going to shift gears for the next series of posts and discuss the importance of understanding the rheological concepts at play in electronic packaging. The discussions so far in this series has primarily focused on the packaging architecture (lead frame, PBGA, flip chip, Fan-out Wafer Level Package) along with some discussion of the types of polymeric materials used in these packages. In order to achieve a good understanding of electronic packaging, one must consider the structure-property-process-performance relationships. We will now turn our attention to processing with specific focus on the flow or rheology during processing.

Why study rheology?

The main advantage of using thermoset resin formulations is that the viscosity in the uncured state can be tailored for the type of processing conditions required. For example, die attach paste is dispensed from a syringe onto a substrate using needle dispensing methods. Many of the important types of formulations used in electronic applications have complex rheological behavior due to high filler loadings (silver, silica, alumina, etc.).

What is rheology?

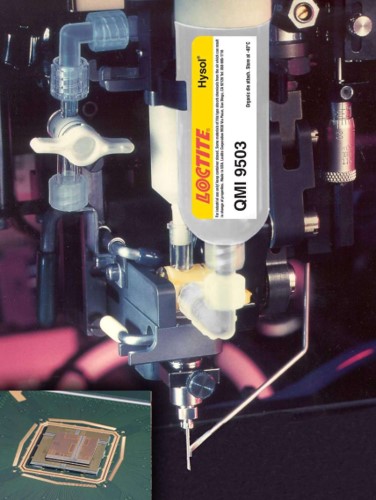

Rheology is the study of flow and deformation under controlled testing conditions. In reality, everything flows, and the amount of flow depends on the time scale. Glass-like materials will flow but only very slowly (at long times) whereas Newtonian liquids will easily flow at short times under very small applied forces. Polymers are an interesting type of material in that they exhibit both elastic (solid-like) and viscous (liquid-like) behavior and are termed viscoelastic. In many electronic packaging applications, the viscous behavior is important during processing. A good example is the dispensing of a highly filled die attach adhesive as shown in Figure 1.

Figure 1. Typical die attach adhesive dispensing set-up (source: Henkel)

The adhesive is supplied in syringes and during dispensing internal pressure in the syringe causes the adhesive to flow through the needle and onto the substrate. The adhesive rheological properties are a key factor controlling the dispensing process. With this in mind, how does one measure the flow or rheological properties of polymers and polymer-based formulations?

There are several experimental methods to measure the rheological properties of polymeric materials. First, there are essentially two types of measurement equipment:

Rheometer

- Instrument capable of measuring the viscosity over a wide range of shear rates or shear stresses

- Measures the viscoelastic properties of fluids, semi-solids, and solids

- Typically used in R&D to probe the viscoelastic properties at various temperatures

- Can be used to follow the viscosity during curing from liquid to solid (very useful for characterizing the curing of thermosets)

Viscometer (most common is the Brookfield)

- Instrument capable of measuring the fluid viscosity over a limited shear rate range

- Measures viscosity at one or two designated shear rates (we will see how a viscometer is used to measure shear thinning in a subsequent post)

- Typically used in Quality Control to measure the viscosity of final formulations in manufacturing

The following posts will focus on rheological methods to characterize polymer-based materials used in electronic applications.

Leave a Reply