Guest Post by Dr. Robert (Bob) Humphreys

History teaches that very large, complex human organizations and systems tend to be inflexible, preferring resistance to evolution when confronted with change. Waste plastic recycling systems and the laws and regulations that govern them are an excellent example. Most plastic in municipal solid waste (MSW) is used food packaging. The world of food packaging evolves rapidly in response to changing consumer habits and tastes, resulting in continuous innovation in package forms, plastics, laminates, and graphics that make the 30-year-old plastic recycle numbering system seem primitive and even obsolete. Regulations can even hamper innovation in recycling technology that is necessary to achieve more effective solutions to the waste plastic problem. In this final post in the series, we will look at a few examples of how packaging market innovation continually stresses established recycling systems and some ways in which regulations can slow adoption of recycling innovation that might produce a more flexible and responsive system that won’t continue to waste the majority of end-of-life plastics through incineration or landfilling.

Complexity from Continual Evolution of Plastic Packaging

The food industry has been altered by the internet, digital communication, biotechnology, and healthy eating trends in so many ways that just listing them might consume this post. A partial list was provided in Post 1 of this series (Dec. 12, 2016) but in keeping with the dynamic nature of the business, big changes have happened since then, such as the purchase of Whole Foods by Amazon. While little is certain in this environment, it is reasonable to assume that such disruptions will have an impact on food packaging volumes and technologies. The impact on recycling is uncertain but increasing volumes of more complex packaging will not be good news for existing systems.

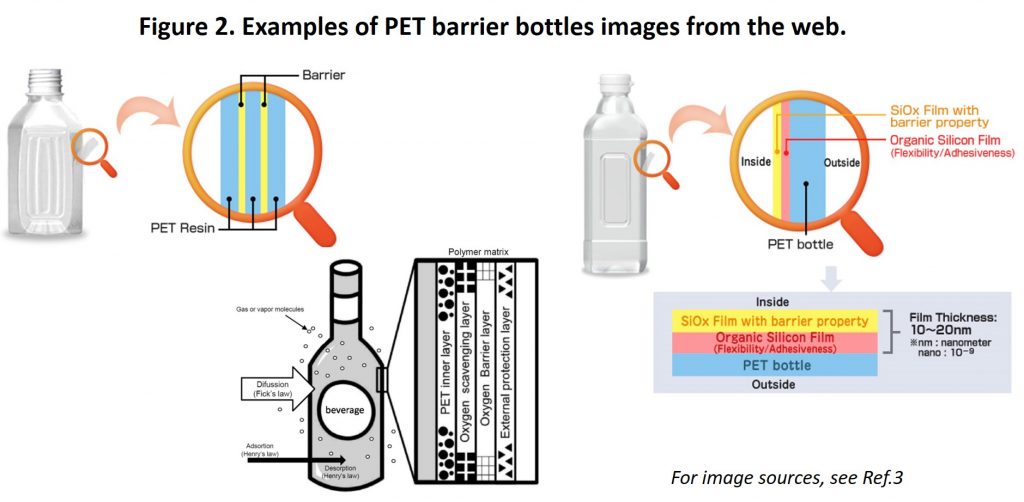

Another example of increasing complexity is innovation in PET (PolyEthylene Terephthalate) bottle technology driven by a need for improved barrier properties (see ref. 2 and figure 2) as well as an approach to product differentiation (see ref. 4). Barrier films can complicate PET recycling if the barrier film cannot be removed easily. Similarly, colored PET complicates waste PET sorting. Also, more PET trays and tubs are found in plastic waste streams, adding more complexity to recycling because these thermoformed PET containers present problems for automated recycling systems. PET is also replacing HDPE (High Density PolyEthylene) in Europe because of the importance of clarity in many packages and because PET is often lower cost than HDPE (see ref. 5). That food packagers respond to cost pressure should come as a surprise to nobody familiar with the business.

As if this was not enough added complexity to deal with, new multi-layer barrier films and novel packaging based on renewable plastics appear in the market regularly. Currently, there is no way to recycle/reuse multi-layer films, so their fate is typically a landfill or incineration. Renewable polymers such as PLA (PolyLactic Acid) are included in plastic recycle category 7, the “All Other” category, which is not recycled. Although PLA use is growing and this plastic can be compostable in an appropriate facility, its fate is typically the same as multilayer films and most other plastic film: landfill or incineration.

Plastic Recycling as a Business

Posts 7-9 in this series described MSW and plastic waste sorting technology that the recycling industry relies on to make recycling efficient enough to be economically viable. Recycling relies on markets that will pay for recycled materials such as metals, paper and cardboard, and plastics. About 9% of plastic in MSW is recycled/reused, with PET and HDPE being the most important, by far, and PP (PolyPropylene) growing. The recycle/reuse market requires clean, high quality post-consumer waste plastic.

Lower quality bales of sorted waste plastic typically are exported. The recent announcement that China will ban imports of plastic waste later in 2017 has sent shock waves through the recycling industry in the USA since about 1.937 million tons of waste plastic was exported by the USA in 2016 (see ref. 7), with most going to China. Income from exported plastic waste is critical to the economic health of the recycling industry and the ban already is having repercussions in the recycling business (for example, see ref. 8 for recycle center closing announcement).

Clearly, a viable, economically sound plastic recycling industry in the USA needs to be able to rely much more on domestic markets rather than depending on export markets for more than half of its products.

Needed soon: A more integrated system for using waste plastic

Today, waste plastic has three probable fates: sorting for recycle/reuse and export; incineration; and landfilling. The last option on this list is under severe stress since landfilling has fallen out of favor in all developed economies. Incineration, even with recovered heat, is a solution that wastes a potentially valuable resource that was generated from petroleum at considerable cost in both energy and CO2 generation. And, finally, recycle/reuse requires high quality (=clean), well-sorted waste plastic that addresses packaging (and other) market needs. Waste plastic that is recycled/reused is not growing significantly as a percentage of overall waste plastic in MSW even as waste plastic is growing at 4% per year.

What is needed is other outlets for waste plastic that are able to deal effectively with some of the issues that plague plastic recycle/reuse. Waste plastic conversion technologies, such as PTO (plastic-to-oil) and pyrolysis to syngas offer opportunities to convert waste plastics to valuable fuels and chemicals that fit well into the existing system of petroleum conversion technology while providing new markets for plastic waste. Posts 11 and 12 described these technologies, including references that provide lists of companies that have commercial processes or are actively scaling up processes. A link to one such company (Agilyx) is provided in ref. 9. Others can be found in ref. 10 and companies commercializing plastic pyrolysis to syngas technologies can be found in reference 11.

As we have pointed out in the past on this blog site, petrochemical production offers a higher value outlet for petroleum compared to fuels and waste plastic film and polystyrene (PS) seem to be excellent raw materials for valuable petrochemicals such as BTX and monomers for plastic production. Nevertheless, most PTO companies sell their “crude” to refineries for upgrading at the present time.

So, in light of the potential of PTO and plastic-to-syngas to address the problems with waste plastic film and “dirty” waste plastic that are unacceptable for recycle, what is delaying wide adoption of these technologies? As always, there is not a single issue that can be pointed to as most important, but regulation is near the top of the list. Simply put, PTO and plastic-to-syngas do not fit neatly into regulatory definitions of “recycling” and face regulatory hurdles (see ref. 11, page 35, Legislative and regulatory uncertainty) such as: are PTO and plastic-to-syngas waste-to-energy or recycling; and, how does “crude oil” from PTO fit into the renewable fuel standard? The slow pace with which such issues are resolved makes little sense in light of the potential benefits these technologies offer to deal with the massive amount of “unrecyclable” waste plastic (and the majority of waste plastic in MSW) that currently finds its way into landfills and incinerators.

References:

1 a) https://www.google.com/search?biw=1094&bih=486&tbm=isch&sa=1&q=supermarket+delivery+images&oq=supermarket+delivery+images&gs_l=psy-ab.3…81233.85997.0.86575.17.17.0.0.0.0.171.2152.1j16.17.0….0…1.1.64.psy-ab..0.7.989…0j0i13k1j0i7i30k1j0i67k1.UHj_hc7e8DU#imgrc=EemSXfbPLAFYeM:

1 b) https://www.google.com/search?biw=1094&bih=486&tbm=isch&sa=1&q=supermarket+delivery+images&oq=supermarket+delivery+images&gs_l=psy-ab.3…81233.85997.0.86575.17.17.0.0.0.0.171.2152.1j16.17.0….0…1.1.64.psy-ab..0.7.989…0j0i13k1j0i7i30k1j0i67k1.UHj_hc7e8DU#imgrc=oiOkszDoYQVWfM:

1 c) https://www.google.com/search?q=food+delivery+images&tbm=isch&tbo=u&source=univ&sa=X&ved=0ahUKEwjs-oKm49TVAhXrr1QKHdiaAZUQsAQIQg&biw=1094&bih=486#imgrc=4X0DcBb8Ge_sHM:

2 https://www.ptonline.com/articles/barrier-pet-bottles

3 a) https://www.google.com/search?q=barrier+films+in+PET+bottles+images&tbm=isch&tbo=u&source=univ&sa=X&ved=0ahUKEwj449u57NTVAhUol1QKHUqRDhEQsAQIJw&biw=1094&bih=486#imgrc=IOYgahxWVPZJLM:

3 b) https://www.google.com/search?q=barrier+films+in+PET+bottles+images&tbm=isch&tbo=u&source=univ&sa=X&ved=0ahUKEwj449u57NTVAhUol1QKHUqRDhEQsAQIJw&biw=1094&bih=486#imgrc=pzhxa44Z2liDEM:

3 c) https://www.google.com/search?q=barrier+films+in+PET+bottles+images&tbm=isch&tbo=u&source=univ&sa=X&ved=0ahUKEwj449u57NTVAhUol1QKHUqRDhEQsAQIJw&biw=1094&bih=486#imgrc=v2mZw_TAWpyJ9M:

4 a) https://www.ptonline.com/blog/post/colored-pet-pretty-to-look-at-headache-for-recyclers-

4 b) https://www.recyclingtoday.com/article/pre-europe-plastics-hdpe-pet-recycled/

5 https://resource-recycling.com/plastics/2017/04/05/packaging-shifts-present-challenges-pet-recycling-industry/

6 a) https://resource-recycling.com/plastics/2017/07/26/wm-plastic-exporters-react-chinas-ban/

6 b) https://www.isri.org/news-publications/article/2017/07/18/isri-statement-on-china’s-intent-to-ban-certain-scrap-imports#.WZC3M1GGOyI

Note: this ban includes mixed paper as well as plastics.

7 https://www.recyclinginternational.com/recycling-news/10403/plastic-and-rubber/united-states/better-start-us-plastic-scrap-exports-2017

8 https://resource-recycling.com/plastics/2017/08/11/qrs-canusa-hershman-will-idle-maryland-prf/

9 https://www.agilyx.com/

10 2015 Plastics-to-fuel project developer’s guide.

11 Gasification of Non-recycled plastic from Municipal Solid Waste in the United States.

12 a) https://www.google.com/search?biw=1094&bih=486&tbm=isch&sa=1&q=bales+of+waste+plastic+image&oq=bales+of+waste+plastic+image&gs_l=psy-ab.3…48979.51675.0.53339.10.9.1.0.0.0.130.995.2j7.9.0….0…1.1.64.psy-ab..0.0.0.SK0RJrqjxXU#imgdii=lEZRH6TNy0Gr1M:&imgrc=_ucEUQKLC-7y0M:

12 b) https://www.google.com/search?biw=1094&bih=486&tbm=isch&sa=1&q=bales+of+waste+plastic+image&oq=bales+of+waste+plastic+image&gs_l=psy-ab.3…48979.51675.0.53339.10.9.1.0.0.0.130.995.2j7.9.0….0…1.1.64.psy-ab..0.0.0.SK0RJrqjxXU#imgrc=5Uh8koCNQVpZDM:

Leave a Reply