In the last post Dr. Bob Humphreys talked about what makes a polymer compostable. I was at a meeting at a local conference center here in Orange County, CA and I noticed the coffee cups. The cup is shown in the picture.

I found some of the labeling interesting. Notice the label states “industrially compostable” which is the proper labeling as we learned from Bob’s post. The other interesting thing I find is the logo with earth choice, You’re making a difference. While true, how many people who use one of these cups actually knows about composting food packaging, let alone industrial composting. The other item to note is that this is a paper cup and it is “lined with NatureWorks® Polymers, made from renewable resources. Interesting. On the bottom of the cup is also the Ingeo logo (from NatureWorks® polylactic acid (PLA)). The cup is made by PACTIV a well-known container manufacturer. The logo in the middle of the cup says renewable, compostable, and sustainable. Interesting labeling because in California it is illegal to label plastic packaging and plastic products as “biodegradable,” “degradable,” or “decomposable.” You may label the product as “compostable” if it meets ASTM D6400, D7081, and D6868. Click here for details.

I found some of the labeling interesting. Notice the label states “industrially compostable” which is the proper labeling as we learned from Bob’s post. The other interesting thing I find is the logo with earth choice, You’re making a difference. While true, how many people who use one of these cups actually knows about composting food packaging, let alone industrial composting. The other item to note is that this is a paper cup and it is “lined with NatureWorks® Polymers, made from renewable resources. Interesting. On the bottom of the cup is also the Ingeo logo (from NatureWorks® polylactic acid (PLA)). The cup is made by PACTIV a well-known container manufacturer. The logo in the middle of the cup says renewable, compostable, and sustainable. Interesting labeling because in California it is illegal to label plastic packaging and plastic products as “biodegradable,” “degradable,” or “decomposable.” You may label the product as “compostable” if it meets ASTM D6400, D7081, and D6868. Click here for details.

Let’s dive in a little deeper. This is a coffee cup, so for a fresh pot, the temperature could get close to 100°C. PLA typically has a glass transition temperature (Tg) in the range of 60-65°C, so for most food packaging applications the use of PLA is limited to cold beverages.

To sort this riddle, the PACTIV website states, “Polylactic Acid coated paper is used for Pactiv’s compostable hot cups and soup cups. While PLA is used for cold applications, when the PLA film is applied to paper such as our hot cups and soup cups, the PLA film takes on the properties of the paper and therefore does not melt or deform. Pactiv’s PLA Lined/Coated Paper Cups are made from 100% annually renewable resources and is ASTM D 6868 certified, compostable and chlorine free in commercial facilities only, which may not exist in all areas.* Not suited for home composting.”

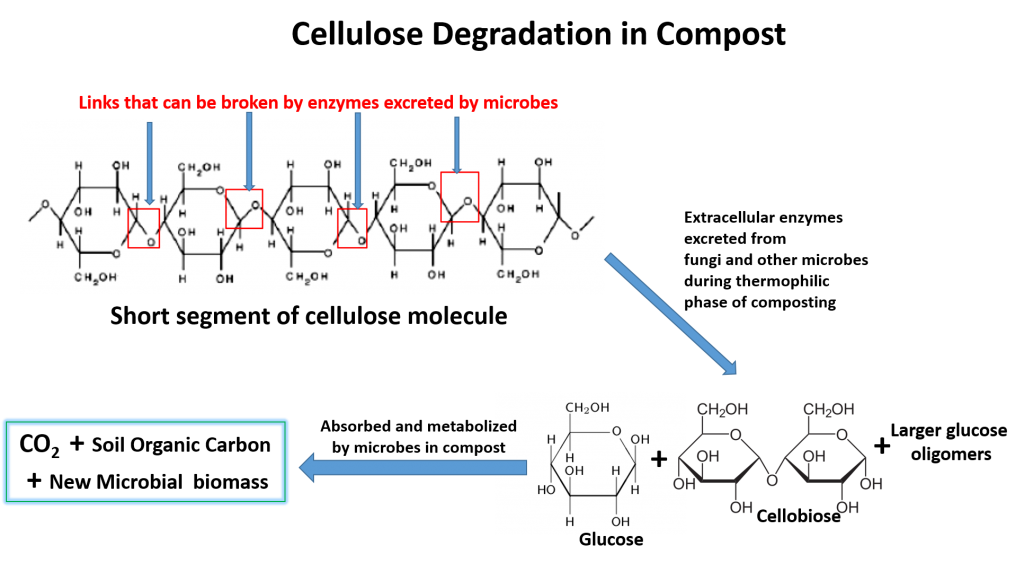

Paper can be manufactured by different processes and can include many different additives and processing aids to ensure that a particular type of paper performs as required by customers. Compostable papers will contain only ingredients that meet composting tests listed above, including requirements for toxicity. Cellulose fibers from wood pulp are the major component of paper. In the “thermophilic” phase of industrial composting, cellulose-degrading enzymes excreted by heat-resistant microbes and fungi break down very large cellulose molecules into smaller fragments (simple sugars and short molecules containing multiple sugars called “oligosaccharides”); the smaller fragments are easily absorbed by the microbes and fungi as a food source. See degradation scheme in the figure below. Some of the cellulosic carbon is converted to new microbes and fungi (growth and cell maintenance), some is incorporated into “soil organic carbon” (a major component of compost that is a critical part of fertile soil), and the bulk is excreted as carbon dioxide (CO2). For paper made from recycled cellulose fibers, starch is often an important ingredient, included to compensate for the reduced strength of fibers caused by the recycling process; starch breaks down easily and typically is consumed by microbes early in the composting process.

The PLA lined paper cup is also a great example of where industrial composting is the most appealing end of life option. The cup itself is a mixture for both a polymer (polylactic acid) and paper (cellulose).

- The cup would not be useful for recycle since it contains two materials impossible to separate and sort.

- Most of the current users will most likely discard the cup in the trash since the vast majority of people have not heard of industrial composting. They may associate composting with the backyard type which is not appropriate for this product.

- The cup will most likely end up in the landfill due to the lack of industrial composting facilities near major municipalities.

- Industrial composting is the best scenario since both the PLA and the cellulose will easily degrade in an industrial composting facility.

A recent development to overcome the lower Tg of PLA, Natur-Tec® BF3002HT was jointly developed between Northern Technologies International Corporation and NatureWorks. The Technical Data Sheet states BF3002HT is a platform of high-performance, biobased and compostable polymer resin compounds made with modified Ingeo™. This platform of resin compounds is specifically engineered for disposable food service applications where high heat performance and dimensional stability are critical. Furthermore, this platform offers a fully compostable alternative to polystyrene or polypropylene in applications such as single use cutlery, disposable coffee pods, and other single use food service ware. The BF3002HT TDS also shows the Heat Deflection Temperature (HDT using ASTM D648) to be 60°C before crystallization and 125°C after crystallization. The heat resistance for cutlery applications is >90°C.

The injection molding process guide for BF3002HT states cutlery used for high-heat applications needs to be annealed (crystallized). The molded objects are annealed either during molding (in-mold annealing) or after molding (post-mold annealing). For example, post-mold annealing is done using a preheated box oven at 95°C ± 5°C for 10 minutes. When using conveyor ovens the line speed should be controlled to ensure a 10 minute residence time in the heated section. In-mold annealing has the potential to significantly increase cycle time (reduce throughput) and most molders use a post-mold annealing process. Another interesting example of polymer physics in action.

This is an excellent put up! It really is stuffed with useful data and It is really written in a straightforward-to-have an understanding of way. I Specially value how the write-up was backed up with investigate and authentic-entire world examples. Nicely accomplished!

Good write-up! Pretty useful and properly composed. You coated The subject in wonderful detail and delivered exceptional illustrations to again up your factors. This information will be a great source for people hunting to learn more about the topic. Thanks for the great get the job done!