Guest Post by Dr. Robert (Bob) Humphreys

One option for disposal of plastic packaging is composting, either in “backyard” or industrial-scale facilities. However, as we have stated in previous posts in this series, there are many problems that must be solved to make composting a viable option for even a small percentage of plastic packaging. There is enough confusion about composting that it is worthwhile to examine the process in more detail. So, in this post, we will examine composting conditions, including what is known about how a material decomposes during composting. This information will provide a background for the next post, where we will discuss compost test methods for polymers and plastics, which should mimic real composting conditions.

What happens during composting?

Compost formation from plant waste is a biological process that involves a broad range of bacteria and fungi from soil that is mixed with the waste plant matter. These microorganisms use plant remains as a food source. Composting usually is an aerobic process, which means it requires a continuous supply of oxygen; hence the need to maintain a “loose”, well-aerated compost pile. Compost formation is a heat-releasing (“exothermic”) process, which means that active compost piles become very warm; heating occurs during several stages and the temperature near the center of a compost heap can reach 105-1700F (41-770C) as the composting process proceeds. This temperature rise is actually necessary for efficient, complete composting to occur (Compost ref 1 for more detailed discussions of the chemistry and microbiology).

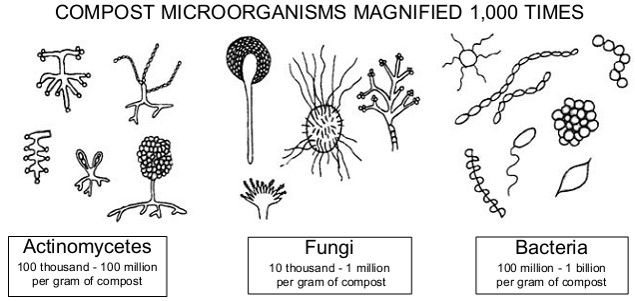

Good soil that is rich in nutrients can contain billions of microscopic organisms per gram, including bacteria, fungi, and other microorganisms. Only a small fraction of soil microorganisms have been identified and characterized, so much is yet to be learned about soil ecosystems. Nevertheless, it is clear that different organisms are active at various stages of composting.

Compost formation is a complex process, involving several distinct stages. Bacteria are important early in the process, when easily-metabolized plant components, such as starches, sugars, proteins, and plant fats are abundant. As these food sources become depleted, bacterial populations decline and fungi populations increase because they secrete enzymes that can feed on the remaining organic matter that is more difficult to break down and metabolize, such as cellulose and lignin (we will spend more time on the nature of these enzymes in the next post, when we discuss what chemical characteristics make a plastic compostable).

As the composting process approaches completion, most of the metabolizable organic matter is consumed and any remaining plant matter is converted to a complex material known as “humus”. Humus varies with the composition of the plant material being composted and the range of microorganisms in the soil mixed with the plant matter. Humus chemical composition does not appear to be settled science, but it is clear that it is organic and very recalcitrant, surviving for decades or more in soil.

Properly prepared compost is not necessarily a rich source of nutrients for soil, but because the high surface area and chemical makeup of humus allows it to absorb and retain soil nutrients and moisture, compost is an excellent soil conditioner. Also, the rich microbiology of compost can add microorganisms to soil that are beneficial to plant growth (see Compost ref 1, page 6 for a more extensive discussion); hence the value of compost in gardening, farming, and soil improvement.

Back Yard versus Industrial Composting

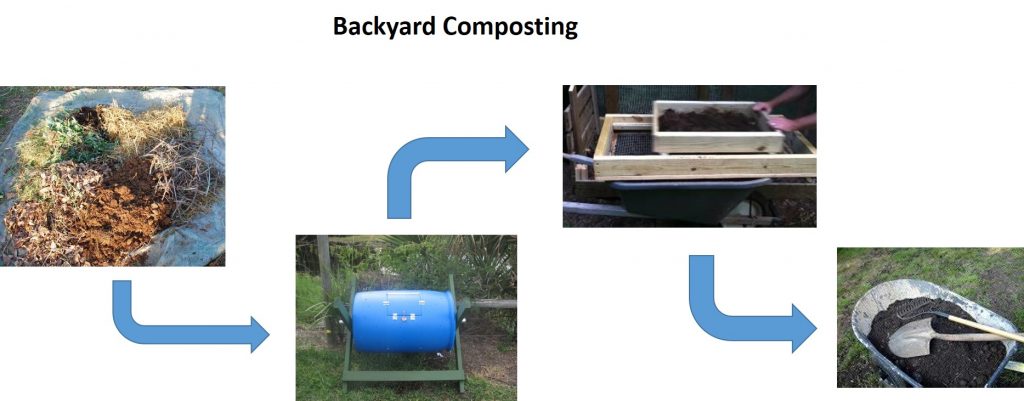

Many home owners have a back yard waste heap, or compost pile, where they place fallen leaves, yard clippings, garden plants that have died, and perhaps even vegetable food scraps from daily meals. Older yard debris at the bottom of the pile shows signs of advanced decomposition while debris added more recently exhibits little decomposition. Decomposition can be accelerated by mulching the debris, by frequently turning the pile, and by ensuring that the pile remains moist. Serious back yard composters may use commercially available composter equipment that facilitates periodic turnover of the decomposing plant matter to enhance aeration and accelerate composting process.

Industrial scale composting is an intensive process in which a broad range of microorganisms (bacteria, fungi) process organic waste (e.g. yard clippings, mulched leaves and branches, food scraps, waste wood, paper, cardboard) to generate humus. Industrial scale composting usually is designed to operate under a range of conditions, depending on the size of the facility and the available capital. Systems that offer optimal composting conditions, such as control of temperature, moisture, continuous aeration, and odor control can handle a few thousand to several hundred-thousand of tons of compost annually, but are more sophisticated and capital intensive. Commercial composting is much faster and more efficient than back-yard composting.

Backyard composting can be a slow and variable process even if it is monitored and good composting practice is followed. This comment is not meant to be discouraging since the purpose of a properly maintained compost heap containing dead leaves, yard clippings, and perhaps vegetable food scraps is usually local gardening, for which it is entirely adequate. Time is usually not a factor since the compost is used when it is available. However, as we will see in the next post, when we examine what characteristics make plastics compostable, most backyard composting conditions are not adequate for disposal of compostable plastics that are in the market today.

As with backyard composting, industrial-scale composting can be variable depending on the sophistication of the process and the type of materials accepted for composting. Composting times for sophisticated systems that include active aeration (i.e. mechanically driven) apparently can be as short as 30 days for the active phase (the “bacterial” phase discussed above) and 30 days for the curing phase (the “fungal” phase discussed above), although much longer times (90-120 days) can apply to both phases if environmental conditions (i.e. temperature, humidity, aeration, type and quality of compost feedstock) are less than optimal. Some industrial composting facilities may be able to take compostable plastics, depending on the sophistication of the technology, the compost production time, and other requirements of the facility.

An excellent, recent publication is available that discusses various compost technology options, including processes, a rough guide to cost, regulations, and where composting is happening (“State of Composting in the US”, https://ilsr.org/initiatives/composting/). Also, there are several professional organizations in the USA and Europe that provide information and guidance on composting (e.g. The US Composting Council, https://www.compostingcouncil.org/, and the Institute for Local Self-reliance, https://ilsr.org/initiatives/composting/; the European Compost Network, https://www.compostnetwork.info/).

In the next post, we will examine the test standards that determine if a polymer or plastic are compostable and, based on this testing, what is known about the characteristics that make a polymer and plastic compostable.

Image Links

- Compost microorganisms image

- Backyard composting images:

Yard clippings mixture, Blue compost drum Compost screen, Finished compost

- Examples of industrial composting technology:

Leave a Reply