Guest Post by Huan Lee, Lambient Technologies

Let’s look at the cure of Sheet Molding Compound (SMC) by measuring ion viscosity and using Critical Points, which I discussed earlier, to characterize the resulting curve. Bulk Molding Compound (BMC) is the generally the same material as SMC but in bulk form, so the results apply to BMC as well. As I wrote in my last post, temperature measurement is one of the essential functions of a dielectric cure monitor, so we can obtain especially useful information by studying the effect of temperature on cure rate.

Procedure

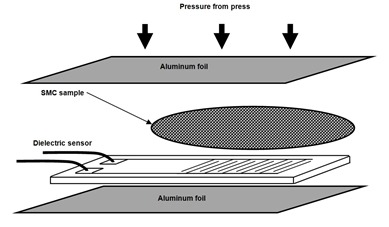

Samples of SMC were applied to disposable sensors then were compressed and cured in a laboratory press at 135 °C, 145 °C and 155 °C. The arrangement of Figure 1 used a sheet of aluminum foil above and below the lay-up to prevent SMC from adhering to the platens.

Figure 1. Lay-up of SMC/BMC on a dielectric sensor

Figure 1. Lay-up of SMC/BMC on a dielectric sensor

Results

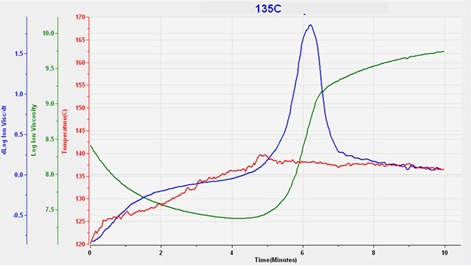

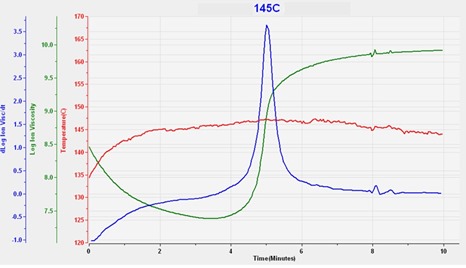

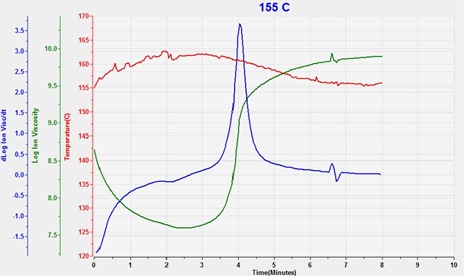

The tests were conducted with a 10 Hz excitation, which was previously identified as an optimum frequency for measuring ion viscosity. Figures 2, 3 and 4 show data from the cures of SMC at 135 °C, 145 °C and 155 °C, respectively.

Figure 2. 135 °C SMC cure at 10 Hz

Figure 2. 135 °C SMC cure at 10 Hz

Figure 3. 145 °C SMC cure at 10 Hz

Figure 3. 145 °C SMC cure at 10 Hz

Figure 4. 155 °C SMC cure at 10 Hz

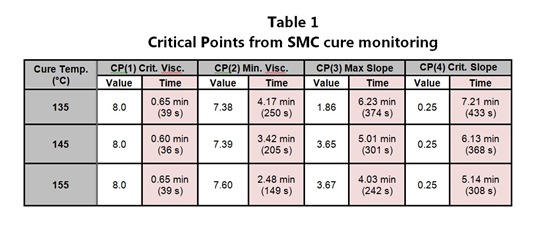

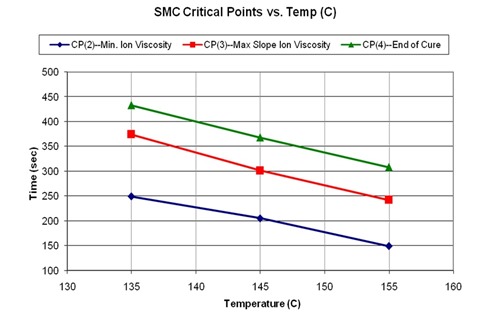

Critical Points identify important features of the ion viscosity curve and give insight into the cure. They are listed in Table 1 and plotted in Figure 5. As expected, the times to reach each Critical Point are shorter for cures at higher temperatures. Note a slope of 0.25 was chosen arbitrarily to identify CP(4)—the end of cure—but for an actual application the user must determine the appropriate slope.

Figure 5. Critical Point time vs. cure temperature for SMC

Many manufacturers of SMC/BMC use dielectric cure monitoring for quality control of outgoing material. By knowing and ensuring the cure time at specified process temperatures, these companies can assure their customers of consistent behavior.

Closed loop process control

For fabricators of end products, dielectric cure monitoring opens the possibility of closed loop process control. Currently, timers determine when to demold parts formed in molds or presses, and must allow for the variation in temperature and other factors that affect cure rate. Demold time is chosen to guarantee that all parts are cured, with the result that some may be processed longer than necessary. Over many thousands of parts, the use of timers wastes considerable time, effort and productivity.

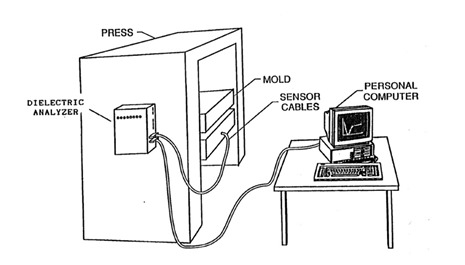

Some time ago, at a company that manufactures commercial SMC products, I set up the hardware of Figure 6 for closed loop process control. A reusable ceramic sensor was embedded in the lower mold. The sensor was coated with mold release before each charge of SMC was loaded. Then the 2000-ton press was closed. Upon detecting end of cure, the dielectric cure monitor automatically issued a signal to open the press.

Figure 6. Closed-loop process control with dielectric cure monitoring (see ref.1)

Figure 6. Closed-loop process control with dielectric cure monitoring (see ref.1)

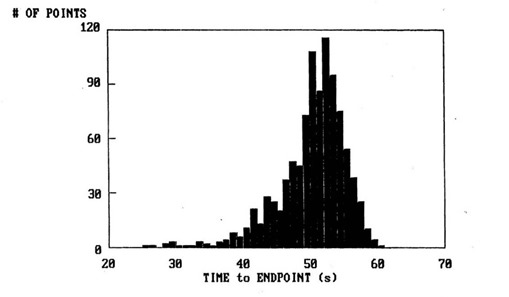

Figure 7 shows the distribution of time to end of cure during the production of about 1000 parts. The fixed timer setting would have been 60 seconds to ensure 100% good parts. In comparison, closed loop control with dielectric cure monitoring reduced average press cycle time to 50 seconds (ref. 1). This 10 second reduction would have saved $70,000/year/press in labor costs alone.

Figure 7. Distribution of SMC cure time for 1000 parts (Ref. 1)

Figure 7. Distribution of SMC cure time for 1000 parts (Ref. 1)

Conclusion

Dielectric measurements allow observation of the cure of sheet molding compound and bulk molding compound in real time, and the extraction of Critical Points quantify the characteristics of the reaction. Dielectric data show the direct correlation between temperature and rate of cure, which can be used in closed-loop process control for more efficient manufacturing.

References

1. Day, D.R. and Lee, H.L., “Analysis and Control of SMC Part to Part Variations,” Session 13-C of Proceedings of the 17th Annual Conference, Composites Institute, the Society of the Plastics Industry, Inc., Feb 3-6, 1992.

Lambient Technologies

209 Newbury Street, 3rd Floor

Boston, MA 02116

617-266-2837

email: info@lambient.com

Leave a Reply