Did you ever wonder what happens to those plastic water bottles or the big liter pop bottles? Some of them get recycled into polar fleece! Who would have thought? A pioneer in PET (polyethylene terephthalate) recycling was the Patagonia outerwear company. Patagonia has a long history of innovating to reduce environmental impact, from using recycled soda bottles in Synchilla® jackets beginning in 1993 to switching to 100% organic cotton in 1996. The Common Threads Garment Recycling Program (info from Patagonia Website) was launched in the Fall of 2005 and marks the latest milestone in Patagonia’s long history of environmental innovation.

Common Threads Program is based on the 4 R’s of Reduce, Repair, Reuse, and Recycle. In order to reduce and use fewer clothes, garments must be made of higher quality and will last a long time. If a zipper needs repair, then customers can have garments repaired if it still has a potentially long life, thus reducing the chance of finding it’s way to a landfill. Then next R is for reuse, where customers can sell or trade for something else or donate to someone who can use the clothing. The last part is recycle.

Through the Common Threads Garment Recycling Program, Patagonia will collect worn-out, old Capilene® base layer garments from customers in order to recycle the garments into new polyester (PET) that will be used to make new filament yarns. Using the ECOCIRCLE™ recycling system from TEIJIN, a progressive fabric manufacturer in Japan, Patagonia’s old Capilene garments can now technically be reprocessed into new fibers.

Using old Capilene garments to make recycled polyester has several environmental benefits. As traditional polyester is made from petroleum, using recycled fibers greatly reduces the fossil fuel based inputs needed to manufacture polyester. The new process also uses far less energy in manufacturing, thus reducing the production of related greenhouse gases such as carbon dioxide. In addition, the program will enable Patagonia to take responsibility for Capilene garments at the end of their useful life. This take-back program will give Patagonia the ability to divert old garments from landfills – in perpetuity, thus eliminating a portion of the plastic waste stream.

Using old Capilene garments to make recycled polyester has several environmental benefits. As traditional polyester is made from petroleum, using recycled fibers greatly reduces the fossil fuel based inputs needed to manufacture polyester. The new process also uses far less energy in manufacturing, thus reducing the production of related greenhouse gases such as carbon dioxide. In addition, the program will enable Patagonia to take responsibility for Capilene garments at the end of their useful life. This take-back program will give Patagonia the ability to divert old garments from landfills – in perpetuity, thus eliminating a portion of the plastic waste stream.

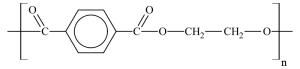

PET monomer can be synthesized by the esterification reaction between terephthalic acid and ethylene glycol with water as a byproduct, or by transesterification reaction between ethylene glycol and dimethyl terephthalate with methanol as a byproduct. Polymerization is through a polycondensation reaction of the monomers (done immediately after esterification/transesterification) with ethylene glycol as the byproduct (the ethylene glycol is directly recycled in production).

The majority of the world’s PET production is for synthetic fibers (in excess of 60%) with bottle production accounting for around 30% of global demand. In discussing textile applications, PET is generally referred to as simply “polyester” while “PET” is used most often to refer to packaging applications. The polyester industry makes up about 18% of world polymer production and is third after polyethylene (PE) and polypropylene (PP).

PET consists of polymerized units of the monomer ethylene terephthalate, with repeating C10H8O4 units. Polyethylene terephthalate is commonly recycled, and has the number “1” as its recycling symbol.

Leave a Reply