Guest Authored with Zoltan Mester, Ph.D,

Common thinking would dictate that polymers from renewable sources would be more sustainable and environmentally friendly. But is this really the case? For polymers, LCA and Green Design evaluations were presented in an outstanding recent paper titled “Sustainability Metrics: Life Cycle Assessment and Green Design in Polymers,” by Amy Landis, et. al., Environmental Science and Technology, September 2, 2010. The work assessed both fossil fuel based synthetic polymers and biopolymers. The fossil fuel based polymers included: polyethylene terephthalate (PET), high density polyethylene (HDPE), low density polyethylene (LDPE), polypropylene (PP), polycarbonate (PC), polyvinyl chloride (PVC), and general purpose polystyrene (GPPS). The biopolymers included polylactic acid via general process (PLA-G), polylactic acid by Nature Work (PLA-NW) (Nature Work is wholly owned company by Cargill Co.), polyhydroxyalkanoate derived from corn grain (PHA-G), and polyhydroxyalkanoate (PHA-S) derived from corn stover. The study also included a hybrid fossil fuel based and bio-based polymer biopolyethylene terephthalate (B-PET).

Common thinking would dictate that polymers from renewable sources would be more sustainable and environmentally friendly. But is this really the case? For polymers, LCA and Green Design evaluations were presented in an outstanding recent paper titled “Sustainability Metrics: Life Cycle Assessment and Green Design in Polymers,” by Amy Landis, et. al., Environmental Science and Technology, September 2, 2010. The work assessed both fossil fuel based synthetic polymers and biopolymers. The fossil fuel based polymers included: polyethylene terephthalate (PET), high density polyethylene (HDPE), low density polyethylene (LDPE), polypropylene (PP), polycarbonate (PC), polyvinyl chloride (PVC), and general purpose polystyrene (GPPS). The biopolymers included polylactic acid via general process (PLA-G), polylactic acid by Nature Work (PLA-NW) (Nature Work is wholly owned company by Cargill Co.), polyhydroxyalkanoate derived from corn grain (PHA-G), and polyhydroxyalkanoate (PHA-S) derived from corn stover. The study also included a hybrid fossil fuel based and bio-based polymer biopolyethylene terephthalate (B-PET).

The LCA evaluations were based using the following parameters:

- Acidification

- Carcinogenity

- Ecotoxicity

- Eutrophication

- Global warming

- Non-carcinogenetic

- Ozone depletion

- Respiratory impact

- Fossil fuel depletion

Green Design was evaluated based on the following parameters:

- Atom economy

- Carcinogens (kg benzene equivalent)

- Non-carcinogens (kg toluene equivalent)

- Respiratory effect (kg PM-2.5 equivalent/liter)

- Ecotoxicity (kg benzene equivalent/liter)

- Cumulative energy use (MJ equivalent/liter)

- Percent renewable material

- Percent recovery

- Biodegradation

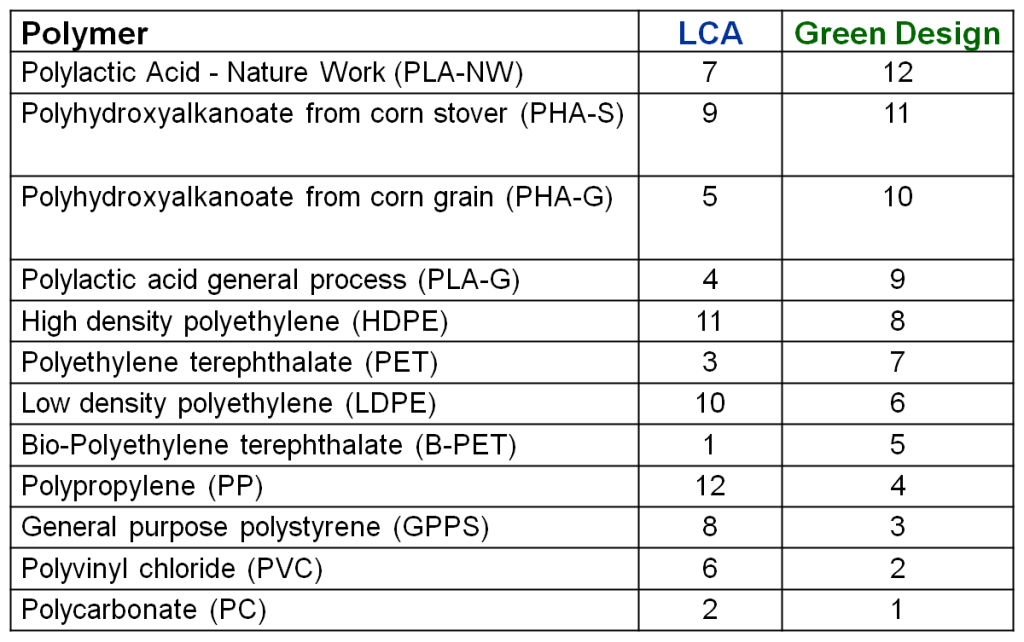

The table below depicts the results for polymer rankings by LCA and Green Design evaluations:

The ranks represent low (worse) to high (better) performance ranking.

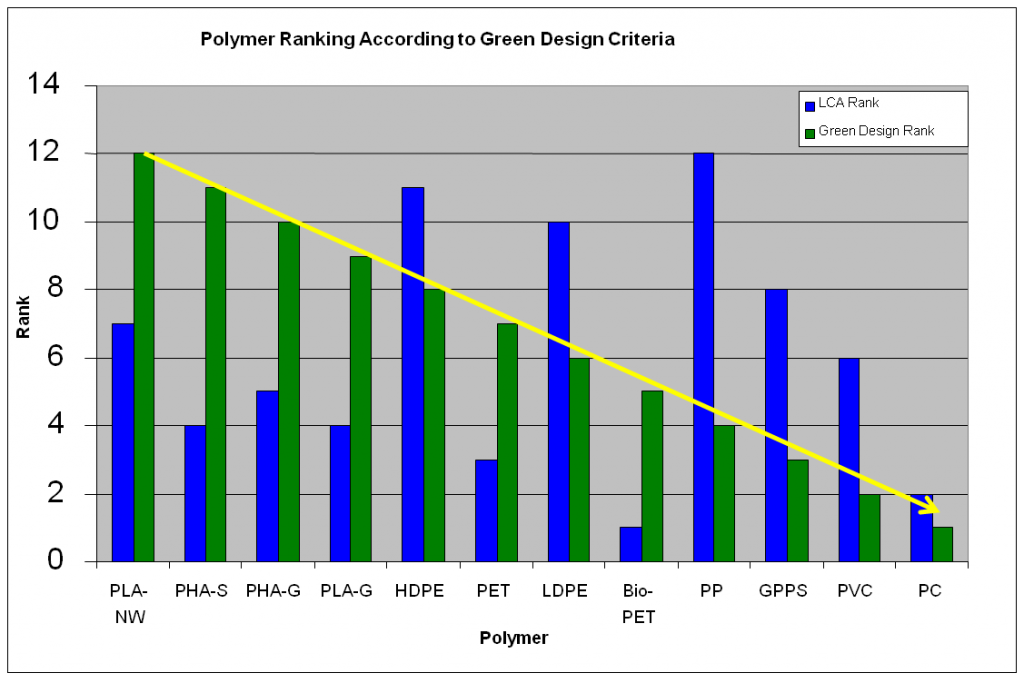

The figure below shows the tabulated ranks plotted according to decreasing Green Design performance and the associated LCA performances:

These results highlight an important finding: LCA ranks and Green Design ranks do not necessarily correlate. For example bio-based polymers have generally the best Green Design performance but they are not the best LCA performers. The reasons for this include that bio-based polymers may need significant process energy to manufacture (fossil fuel energy needed for grinding, distillation, extraction, etc.), fertilizer needs, pesticide and herbicide use, water supply and potential for causing ecological depletion of resources.

Considering the LCA ranks, traditional fossil fuel based polymers PP, HDPE and LDPE were the best performing polymers. Remarkably for HDPE and LDPE, atom economy is 100 percent since they are manufactured by addition reactions and for this specific parameter they are good green chemistry polymers.

It should be emphasized that the results of LCA and Green Design studies depend on the specific parameters chosen for the evaluation. For example fossil fuel energy requirements can be reduced if renewable energy sources are available (solar, hydroelectric, wind, biomass), atom economy can be improved by newly discovered catalytic conversions, and for bio-based materials genetic engineering, although not without controversy, can reduce pesticide and herbicide use. The very notion that a chemical substance, including a polymer, is labeled “green” “organic” or “natural” also depend on industry accepted ratings (such as the product 95 percent naturally derived) and these ratings are constantly evolving and not without controversy.

For more details on the study methods, interested readers are encouraged to get “Sustainability Metrics: Life Cycle Assessment and Green Design in Polymers,” by Amy Landis, et. al., Environmental Science and Technology, September 2, 2010.

I’m keen with interest to work on Recovery and Reuse of “solid mix waste recovery and reuse into valuable products”. With over a past 6 years of experience in chemical laboratories & working on 17 different projects for government of India helps me to endeavor to put wheel into motion & got influenced from your immersed research in “Innovative research of waste into energy”. Recently, I’m working with government of India, taking initiative step for building world’s largest power sector producing (9700MV) from a solar cell by 2021 & also working on “Novel Technology to build biodegradable plastic from waste”.

Throughout my academic and industries experiences, I received training in conducting studies and literature searches using database, analyzing and summarizing data. I gained experience in recovery & reuse rather than doing recycling. Qualitative and quantitative analysis of during entire work was not only on e-waste but also doing “Sublimation of olefins waste into fuels”, “Final Degradation of Compact Disc”, Aerogel Synthesis” & Recovery of vinyl chlorides & Bisphenol -A from thermoset materials….Green approach of waste into energy was the central motive of my project. One of previous project was on “Extraction and Recovery & Reuse of E-waste composites by Ionic liquid” & was awarded best project of the year by Government of India in 2014. Extraction of Gold, Platinum….etc precious metals recovery and reuse was vital and very must from e-waste and probably many of analysis can be done like reacting with Dimethyl sulfoxide (DMSO), 1-ethyl 3-methylimidazolium tetrafluoroborate, Sodium cyanide, leaching process (Nitric acid) and many more .

Recently, I developed a project for Asia’s largest landfill (solid mix waste) in Ahmadabad:- city of Gujarat state, India) and was conclude one of the best project on solid waste management by Mr. Prime Minister of India, and also have developed “Green House Gases convert into Bioplastics” and is very challenging to world to reduce pollution almost. However, I’ll be privileged and honor to work at on solid waste to make world green and clean, if you give me an opportunity once. I have enough potential and caliber to get BEST from WASTE.

I’ll like to take an opportunity to send all my work regarding novel projects of e-waste, plastics, agro, wood…etc, if interested.