Guest Post by Dr. R. Bruce Prime

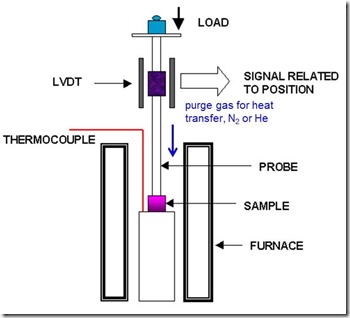

Thermomechanical analysis or TMA is a simple yet very useful technique that can measure coefficient of thermal expansion, Tg and the dimensional change accompanying the relaxation of stress stored in a material. As shown in the illustration the dimensional change of a material with temperature (or time) is measured in a controlled atmosphere and under controlled load. Measurements may be made in compression (shown) or in tension, e.g. on a film or thin sample. A good reference for TMA as well as the other thermal analysis techniques is Thermal Analysis of Polymers: Fundamentals and Applications, (JD Menczel and RB Prime, eds), Wiley, 2009.

Thermomechanical analysis or TMA is a simple yet very useful technique that can measure coefficient of thermal expansion, Tg and the dimensional change accompanying the relaxation of stress stored in a material. As shown in the illustration the dimensional change of a material with temperature (or time) is measured in a controlled atmosphere and under controlled load. Measurements may be made in compression (shown) or in tension, e.g. on a film or thin sample. A good reference for TMA as well as the other thermal analysis techniques is Thermal Analysis of Polymers: Fundamentals and Applications, (JD Menczel and RB Prime, eds), Wiley, 2009.

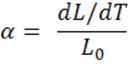

The coefficient of linear expansion (a) is abbreviated CTE or CLTE. L is sample length, L0 the initial sample dimension, usually at ambient temperature, and T is temperature in °C. a has the units of ppm/°C or m/m/°C. The CTE of a material is often an important property, e.g. when trying to match the expansion coefficient of one material bonded to another material such as copper in order to minimize thermal stresses. CTE can also be a valuable tool to characterize anisotropy. For isotropic materials ax = ay = az, but for filled or composite materials CTEs are often non-isotropic with unique values in the x, y and z-directions, as we will see in the next post.

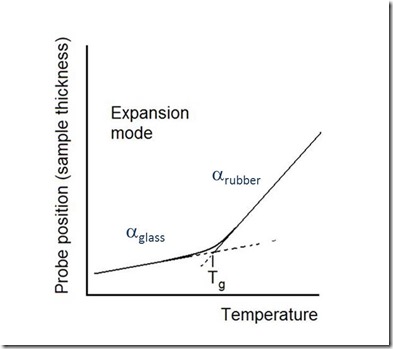

As shown above TMA in the expansion mode is used to measure CTE and Tg. In this measurement the load is small, just enough to keep the probe in contact with the sample so as not to interfere with the measurement of expansion. The probe diameter is typically 2.5 to 3 mm. The sample needs to have flat parallel surfaces. Sample diameter can be larger or smaller than the probe diameter and its thickness is typically a few mm. This measurement is commonly preceded by a 1st heat to but not beyond Tg to relieve any internal stress so that pure expansion and Tg of the original material may be observed on the 2nd heat. The extrapolated intersection of the glassy and rubbery expansion curves is considered to be a precise measurement of the glass transition temperature. Note that CTE in the rubbery phase is about 3x that in the glassy phase.

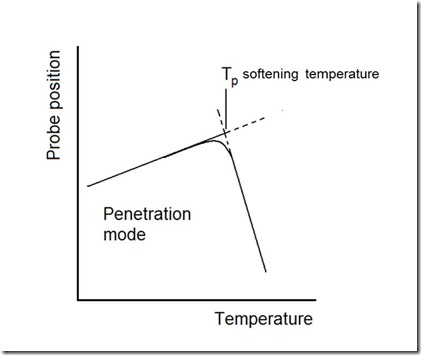

TMA in the penetration mode is useful for measuring the softening temperature Tp as an approximation to Tg. This measurement is less rigorous, can be performed more quickly and is useful when only the transition temperature is of interest. A high force is used and the probe diameter is small, e.g. 0.5 to 1 mm to promote penetration into the sample. A similar measure of Tp can be made on a very small piece of material, e.g. an adhesive, by placing it under the expansion probe.

Thin films or prepregs can be measured in the extension mode shown above where the longer sample dimension gives increased sensitivity for measuring CTE of low expansion materials and the thinner samples equilibrate more quickly with water allowing measurement of the lowering of Tg with water sorption as well as hygroscopic expansion.

In the next post we will explore applications of TMA to thermosets.

Leave a Reply