Guest Post by Dr. Robert Humphreys

Generation Y and Z may teach their grandchildren that replacing petroleum and coal by renewable energy, chemicals and polymers was a mission that defined the first 50 years of the New Millennium and distinguished “their time” from the fossil carbon dependence of previous generations. On the other hand, a cynical history professor might teach the same children that their parents were simply rediscovering the past. Indeed, boomers like yours truly can remember a time when all fabrics were cotton, rayon, linen or wool, rubber came from trees, photography required celluloid film, floor tiles were linoleum, wood furniture was coated with shellac, detergents were mostly soap flakes, and turpentine was required to remove paint from a paint brush. The omnipresent media mega-barrage of hype about biofuels, renewable materials, “organic” foods, and “all natural” shampoos, toothpastes, and cosmetics makes it is easy to forget that humans relied on natural, renewable materials to improve their quality of life and longevity from prehistoric times until the early 1900’s. In contrast, petroleum has dominated human energy and material needs for only the last century.

Generation Y and Z may teach their grandchildren that replacing petroleum and coal by renewable energy, chemicals and polymers was a mission that defined the first 50 years of the New Millennium and distinguished “their time” from the fossil carbon dependence of previous generations. On the other hand, a cynical history professor might teach the same children that their parents were simply rediscovering the past. Indeed, boomers like yours truly can remember a time when all fabrics were cotton, rayon, linen or wool, rubber came from trees, photography required celluloid film, floor tiles were linoleum, wood furniture was coated with shellac, detergents were mostly soap flakes, and turpentine was required to remove paint from a paint brush. The omnipresent media mega-barrage of hype about biofuels, renewable materials, “organic” foods, and “all natural” shampoos, toothpastes, and cosmetics makes it is easy to forget that humans relied on natural, renewable materials to improve their quality of life and longevity from prehistoric times until the early 1900’s. In contrast, petroleum has dominated human energy and material needs for only the last century.

Naturally derived, renewable chemicals and materials still dominate or are important parts of many items we take for granted in our everyday lives. While these renewables once were provided by industries associated with extreme environmental pollution, more recently they have become outstanding examples of clean, energy-efficient manufacturing, producing vast quantities of environmentally friendly, renewable materials and chemicals. Any honest series of articles on biomass feedstock needs to mention some examples of such products lest we forget that “natural” and “renewable” are old ideas.

Starch: Good Carbs On Paper

Starch is “bad carbs” if you listen to the infomercial food hucksters selling magic weight loss products. Nevertheless, starchy foods are the main source of nutrition for a majority of the world’s population. Less recognized is the critical role starch plays in many manufacturing processes; a partial list (Corn Refiners Assn. 2012 Report):

- Paper making: starch and modified starch is used in four steps of the paper making process. Starch is a key component of coatings that improve paper printing. Starches also improve the strength of recycled paper products to compensate for fiber damage caused by the recycling process. After cellulose fiber, starch is the second largest component of paper.

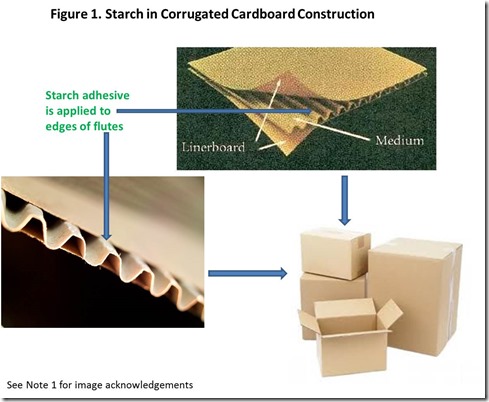

- Corrugated packaging: starch is the main component of adhesives used to make corrugated cardboard (see Figure 1).

- Paper products: most paper bags and envelopes are constructed with starch-based adhesives.

- Textile manufacture: machine weaving, cloth finishing, and cloth printing depend on starch-containing sizing, coatings, and dying pastes.

- Drilling for oil and gas: corn starch is a component of many drilling muds that lubricate drill bits.

- Medicine and pharmaceutical delivery: starches are often a critical part of the binder used in pill manufacture.

Next time you print with your office ink jet, think starch.

Pine chemicals: From the Forest to Your Chewing Gum

Paper making generates large quantities of renewable chemicals, pine terpene and tall oil products being the most important. Chemicals and polymers made from terpenes and tall oil are functional components of many products that we use or experience every day. Some examples (pine chemicals ):

- Terpenes can be polymerized to resins that can replace petroleum-based hydrocarbons in adhesives. They also are used in inks.

- Terpene monomers are natural products that have applications in flavors and fragrances.

- Tall oil fatty acid based chemicals and polymers are employed in a huge range of products, such as protective coatings, resins for printing, cosmetics and personal care products, lubricants, cleaning agents, and corrosion inhibitors.

- Tall oil rosin chemicals are used in applications as diverse as flavor stabilizers in beverages, chewing gum, hot melt adhesives, printing inks, and road marking.

- Even tall oil pitch components, essentially the “bottoms” after separating fatty acids and rosin, are employed in products such as nutraceuticals and biofuels.

In keeping with the season, a pine tree can be much more than just a Christmas tradition.

Cellulose: Much More Than Paper

Virtually everyone has garments made of cotton. Cotton is almost pure cellulose, as is linen, a fiber made from the flax plant. Cellulose is the most abundant biologically produced polymer on earth (see cellulose biofuels). The cellulose in cotton and linen is not chemically modified. However, cellulose can be modified chemically to give polymers and other materials found in many everyday products. Some examples:

- Cellulose acetate (acetate fiber) is made from wood pulp cellulose by treatment with acetic acid or anhydride. Acetate fiber is still used today for garments, drapery, upholstery, and cigarette filters.

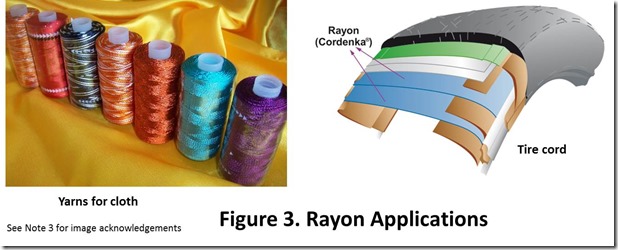

- Rayon is prepared by treating cellulose with carbon disulfide under basic conditions. The process introduces xanthate groups onto the cellulose structure (see Figure 2). Rayon, also known as “viscose”, is used in many products, including garments, nonwoven products such as disposable diapers, and tire cord (Rayon uses, Tire cord). Rayon is biodegradable by composting and is more water absorbent that cotton fiber.

- Cellulose ethers (Cellulose ethers 1; Cellulose ethers 2) are used in a wide range of formulated products for thickening, controlling flow (rheology), coating, suspending, and binding. Some examples of formulated products containing cellulose ethers include construction products (tile pastes and grouts, mortars, plasters, sheet rock, adhesives), personal care products (shampoos, creams, hair styling products), pharmaceutical (tablet coatings, controlled release), and foods (bakery, fruit fillings, salad dressings).

Rayon and Acetate demonstrate that old technologies can thrive for many generations if they continue to provide acceptable economic value to producers and customers.

Old Doesn’t Have to Mean Obsolete

Space limitations have forced us to be selective and not mention many other “natural” and “renewable” technologies in use today that were developed decades or even centuries ago. It is sometimes humbling for a technologist to remember that the wood in a Stradivarius was cut, shaped, glued together and varnished with renewable materials over 300 years ago.

Notes:

1. Images in Figure 1 from; corrugating process image 1 ; corrugating process image 2 .

2. Images in Figure 2 from https://www.borum.as/images/fotoalbum/small/Extrusion_in_progress.JPG ; https://ecoloinfo.com/wp-content/uploads/2009/06/chewing_gum.jpg

3. Images in Figure 3 from https://www.cordenka.com/en ; https://www.kangaroothreads.com/images/home/vicose_%20rayon_%20filament_1.jpg ;

Leave a Reply