How many of us have confronted a massive problem in your business that is really holding your company back? Typical examples are production problems leading to large scrap losses, scheduling delays due to capacity issues, new product failures after launch. This list goes on.

Where do you start to sort through the issues. I have worked on some “hairy” problems over my career and I learned one thing:

“What most people think is the cause of the problem will turn out to be wrong.”

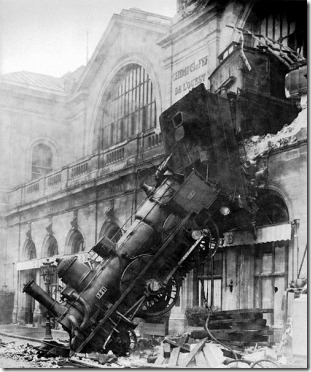

This never fails to hold true. So how do you start? First you must use a systematic approach. Random experiments, shoot from the hip solutions, and other advice from the experts will waste time and lead to a bigger train wreck. Assuming you have put in place a dedicated multifunctional task team, a good place to start is to form a “war room” where you can plaster flip charts on the wall (with Post-it notes for ideas, work items, tasks, etc.) to get all the information out in the open. I call this the initial data dump. No solutions, just get all the data you can find and get it posted for the team to view. Until you get all of the data on the table (or wall in this case!) you won’t be in a position to carefully evaluate the situation. The next steps depend on your approach. If you use Six Sigma, then there is a defined methodology called DMAIC which stands for Define, Measure, Analyze, Improve, and Control. In each of the 5 phases, there are well established tools and methods to work on the problem.

If you don’t have Six Sigma training, you can also use a similar type of approach that might not be as rigorous or process focused, but the first thing in any case is to define the problem.

I want to emphasize again that you don’t want to start looking for solutions from the onset. This seems a bit odd, since for most train wrecks there is a huge sense of urgency. Resist at all costs or you’ll pay in the long run. If you don’t have all of the data upfront, then as you work through the measure phase, you won’t know what to measure or look for. Spending time defining the problem is the key to success. As most medical doctors know, the hardest part is making the correct diagnosis since once the diagnosis is known, there are usually proven treatments available.

Both in my corporate life and in my consulting business, I see the same thing over and over again. People look at the train wreck and start working on “perceived solutions” using a shotgun approach. I have found these initial hunches are mostly wrong, only address part of the problem, and lead to wasted time. Time spent wisely upfront defining the problem and getting all the data available pays dividends in the long run.

In the next post we will dive a little deeper into the “art of solving train wrecks.”

(image credit: Studio Lévy and Sons)

Leave a Reply