3-Part Advanced Thermoset Cure Kinetics Video Series

Presented by Dr. R. Bruce Prime

Basic Cure Kinetics

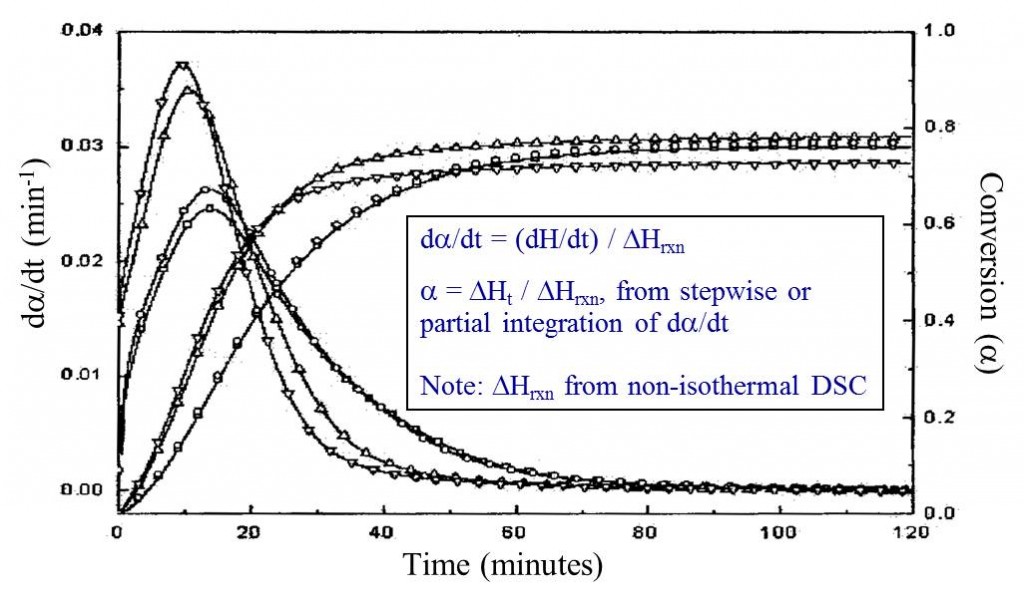

Do you need to determine how fast your thermoset cures? Change the curing time or temperature to optimize curing but don’t know where to start? Most thermoset cure reactions follow nth order or autocatalytic cure kinetics. In this video you will learn:

- how to perform isothermal DSC and TGA cure experiments

- how to distinguish nth order from autocatalytic reactions

- how to analyze DSC and TGA curves to extract cure parameters such as reaction order, pre-exponential factor and activation energy.

Practical Cure Kinetics

Do you want to measure the kinetics but don’t know much about the curing chemistry? You’ve come to the right video since neither of these methods requires knowledge of the chemical reaction model. Both are isoconversional methods that measure activation energy from time or temperature to fixed conversion. In this video you will learn:

- how to conduct model-free kinetic analyses on multiple heating rate DSC experiments

- how to analyze these curves to measure activation energy and construct activation energy – conversion curves

- how to apply time-temperature superposition techniques to obtain master cure curves, and 4) how to determine the entire kinetic equation for a fast-curing polyurethane system and model the curing for an actual mixing and curing process.

Kinetic Measurements Using Dynamic Mechanical Analysis (DMA)

During processing, do you need to know how the viscoelastic properties change as a result of cure chemistry? Kinetic viscoelasticity measures how the viscoelastic parameters change as a result of chemical cure reactions. DMA measures property changes due to reaction, including gelation, elastic modulus (proportional to cross-link density), and Tg (measure of cure through the Tg – conversion relationship). In this video you will learn:

- how to extract kinetic parameters from isothermal DMA measurements

- how to use kinetic viscoelasticity as an aid to interpreting dynamic DMA curves of uncured and partially cured thermosets.

So what is your investment to improve your skills in advanced kinetics and become the “go-to” person in your lab?

The Best Value is the Three part video series for $249. Why wait? Click the Buy Now button to enroll in our information packed 3-part video series.

Here’s the great value you will receive for your investment:

-

Recording of the audio and video from the online event.

-

Copy of the presentation slides in pdf format

-

Transcription (eBook) of the audio portion for those who prefer to study a written document

All of the content will be available for download and further study in your members area.

Remember, the best deal is the 3-part video series for $249. Go ahead and click the Buy Now button to get started!

If you would like to purchase individual videos, they are available for $99 each.

Basic Cure Kinetics

Practical Cure Kinetics

Kinetic Measurements Using Dynamic Mechanical Analysis (DMA)

Faculty

R. Bruce Prime, Ph.D. is a co-founder of Thermoset University, a technical consultant and recognized authority on the cure and properties of crosslinked polymer systems. In his thirty-year IBM career he led teams responsible for developing and implementing polymer applications for printer and information storage technologies. He holds four patents and is the author of more than 50 technical papers and the chapter on Thermosets in Thermal Characterization of Polymeric Materials (E. A. Turi, editor, 1981, 1997). Dr. Prime is a fellow of the Society of Plastics Engineers (SPE) and the North American Thermal Analysis Society (NATAS) and was the 1989 recipient of the Mettler-Toledo Award in Thermal Analysis. In 1980 he co-founded what is now the Golden Gate Polymer Forum where he remains on the board of directors. Bruce obtained his Ph.D. in Chemistry from Rensselaer Polytechnic Institute with Dr. Bernard Wunderlich.

R. Bruce Prime, Ph.D. is a co-founder of Thermoset University, a technical consultant and recognized authority on the cure and properties of crosslinked polymer systems. In his thirty-year IBM career he led teams responsible for developing and implementing polymer applications for printer and information storage technologies. He holds four patents and is the author of more than 50 technical papers and the chapter on Thermosets in Thermal Characterization of Polymeric Materials (E. A. Turi, editor, 1981, 1997). Dr. Prime is a fellow of the Society of Plastics Engineers (SPE) and the North American Thermal Analysis Society (NATAS) and was the 1989 recipient of the Mettler-Toledo Award in Thermal Analysis. In 1980 he co-founded what is now the Golden Gate Polymer Forum where he remains on the board of directors. Bruce obtained his Ph.D. in Chemistry from Rensselaer Polytechnic Institute with Dr. Bernard Wunderlich.

Visit his web site at www.primethermosets.com to get more information on thermosets, including thermal characterization.