By Dr. Jeff Gotro

Have you ever had a question about measuring the rheological properties of thermosets?

Have you ever had a question about measuring the rheological properties of thermosets?

Didn’t know what is the right experimental approach to get the right rheological information?

Need to measure the viscosity-shear rate for an uncured thermoset formulation?

Had a question on how does the rheology relate to the curing process?

Wondered how the viscosity profile impacts the composite fabrication process?

Would like to see a “real life” example in a case study on the lamination of a thermoset composite?

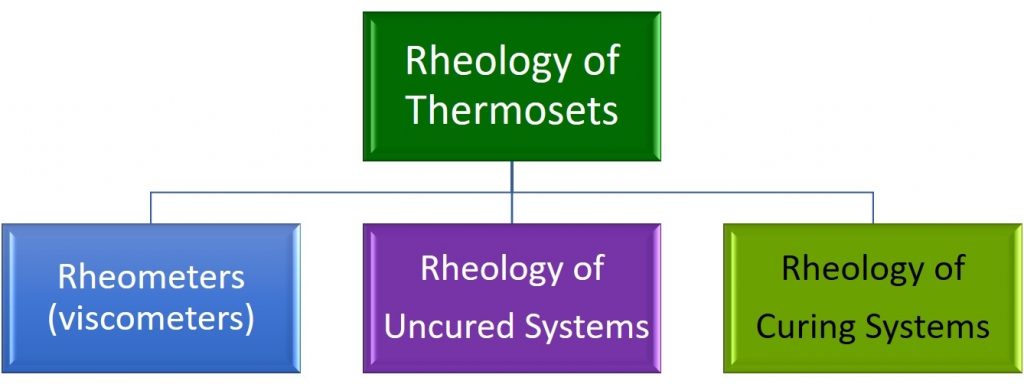

The Rheology of Thermosets has been significantly updated and expanded to cover:

-

What is rheology and how it relates to thermosets

-

How curing chemistry impacts the rheology and flow during processing, that is the chemorheology of thermosets

-

Rheological methods used for thermosets; controlled stress and controlled strain measurments

-

Rheological measurements on uncured formulations; viscosity-shear rate, shear thinning, thixotropy

-

How to measure the Isothermal rheology during curing

-

Non-isothermal rheology during curing

-

A comprehensive case-study demonstrating some of the key concepts of rheology during thermoset processing