Wishing all of our readers a safe and Happy Halloween! PS: Dr. Prime will continue his series on cure kinetics on Monday. More good stuff to come! ... [Click to Continue...]

Thermoset Cure Kinetics Part 1: Introduction to Kinetics

Guest Post by Dr. R. Bruce Prime This is the first post in a new series on Thermoset Cure Kinetics, where we introduce the basic principles of kinetics and their general application to thermoset cure. In the following posts we describe important applications to the characterization and design of thermoset cure processes. A common dictionary definition for kinetics is the ... [Click to Continue...]

Rheology of Thermosets Part 10: Putting it All Together to Study a Composite Lamination Process

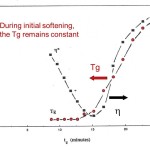

In previous posts we set the stage for understanding how the viscosity profile changes during non-isothermal curing. We showed how heating rate changes the minimum viscosity, how during the initial softening of a B-staged prepreg, the viscosity is dominated by the temperature dependence and when using latent hardeners, there is no chemical reacting during the initial viscosity ... [Click to Continue...]

Rheology of Thermoset Part 9: Correlation of the Viscosity, Tg, and Conversion During Non-isothermal Curing (part three)

In our last post we showed how the chemical conversion and glass transition temperature (Tg) were correlated to the viscosity during a non-isothermal curing profile. We will continue our analysis of the aborted rheometer data in this post. In the data presented in Part 8, the heating rate was held constant. In reality, we did experiments at several heating rates and the ... [Click to Continue...]

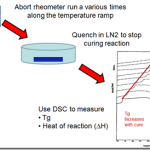

Rheology of Thermoset Part 8: Correlation of the Viscosity, Tg, and Conversion During Non-isothermal Curing (part two)

In our last post we provided the background on how to correlate the viscosity, conversion, and Tg during non-isothermal curing. We used the technique in the figure to the left to “freeze the action” along the viscosity profile and use DSC to probe how the curing was progressing. In the next figure, the percent conversion is plotted as a function of time on the left axis and ... [Click to Continue...]