Guest Post by Dr. R. Bruce Prime In the previous post we showed how MTDSC in the heating mode can be used to provide insight into the cure of thermosets that cannot be obtained by standard DSC. Here we show how MTDSC in the quasi-isothermal or QiDSC mode can be used to characterize thermoset cure. Isothermal measurements are often preferred when ... [Click to Continue...]

MTDSC of Thermosets Part 2: Nonisothermal Cure

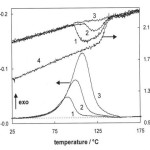

Guest Post by Dr. R. Bruce Prime In the previous post we introduced modulated temperature DSC and described the basic principles. Here we show how MTDSC can be used to provide insight into the nonisothermal cure of thermosets, much of which cannot be obtained by standard DSC. The figure below shows the MTDSC of an uncured amine-epoxy system at 1 ... [Click to Continue...]

MTDSC of Thermosets Part 1: Introduction to Modulated Temperature Differential Scanning Calorimetry

Guest Post by Dr. Lawrence Judovits, Arkema, and Dr. R. Bruce Prime We welcome back Dr. R. Bruce Prime along with fellow thermal analyst Dr. Larry Judovits from Arkema for a series of posts on MTDSC. Modulated temperature differential scanning calorimetry (MTDSC) is a family of techniques where a temperature modulation is overlaid on a linear heating or cooling ramp ... [Click to Continue...]

Rheology of Thermosets Part 18: Lamination Case Study – 8

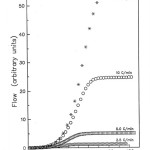

In the last post we discussed how changing the resin content and the prepreg degree of B-stage advancement impacted the flow during lamination and the viscosity profile during non-isothermal curing. Another technique used to tailor the flow during processing is to vary the curing kinetics. Typical thermosets have a reactive resin and a hardener (crosslinking agent). Some ... [Click to Continue...]

Rheology of Thermosets Part 17: Lamination Case Study – 7

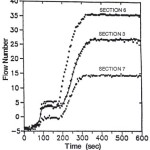

The prepreg resin content and degree of B-stage advancement (percent conversion) were shown to have an impact on the flow during lamination. As presented in the previous post, the figure on the left shows the flow number for several specially prepared prepregs. To validate that the flow number obtained using the squeezing flow was close to the flow number measured ... [Click to Continue...]