I trust all my readers had a nice relaxing holiday season and are ready to start the new year. At Polymer Innovation Blog, we have an exciting line-up planned for 2016. We have a series of guest blog posts lined up authored by several InnoCentrix consultants: Dan Lamone will have an extensive series on UV curing Dr. Robert Humphreys will be back with updates on the ... [Click to Continue...]

Happy Holidays and Best Wishes for a Prosperous New Year

At this time of the year it is great to be able to spend time with family and friends and reflect on all of our blessings over the past year. Best wishes to all my readers for a safe and relaxing Holiday Season and Happy New Year. Back by popular demand in our “chemistree” ... [Click to Continue...]

Fillers in Action: Electrically Conductive Thermosets

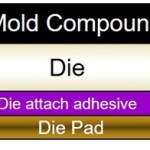

Over the last several posts we have been discussing how fillers can be used to significantly modify the physical properties of thermosets including lowering the coefficient of thermal expansion (CTE) and increasing the thermal conductivity. In this post we will discuss some ways fillers can be used to make electrically conductive thermosets. A good example of an electrically ... [Click to Continue...]

Fillers in Action: How to Achieve High Particle Loadings, Part Two

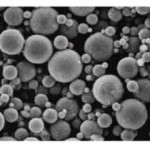

In the last post we introduced the concept of using a multi-modal particle size distribution to achieve very high packing densities (filler loadings) in thermoset compounds. Remember that applications such as mold compounds, capillary underfills, and some types of encapsulants need to have a low coefficient of thermal expansion (CTE). Epoxy resins (and other thermosets) ... [Click to Continue...]

Fillers in Action: How to Achieve High Particle Loadings

In the last two posts we saw how important fillers can be in improving the properties of thermosets. We have covered using thermally conductive fillers to enhance the thermal conductivity of thermoset formulations. Additionally, we saw how the coefficient of thermal expansion (CTE) could be significantly lowered with judicious use of fillers. In many cases it is advantageous ... [Click to Continue...]