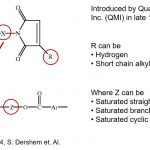

In the last post the history of epoxy die attach was discussed. Up until the late 1990’s epoxy was the main thermoset resin used in both conductive and non-conductive die attach. With the drive to get to higher JEDEC moisture sensitivity levels (level 2/260°C and eventually to level 1/260°C) resins with significantly lower moisture absorption were needed. Additionally, ... [Click to Continue...]

Polymers in Electronics Part Nine: Die Attach Adhesives Part 2

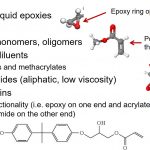

The last post introduced the basics for die attach adhesives. This post will provide more details into the chemistry of die attach adhesives over time. The one of the first uses of die attach adhesives was to attach the semiconductor chip (or die) to a leadframe substrate as seen in the schematic cross-section on the left. The following chart depicts the ... [Click to Continue...]

Polymers in Electronics Part Eight: Die Attach Adhesives Part 1

This post will continue our discussion of polymers in electronics by taking a step back and looking at one of the most widely used polymer-based adhesive in electronics: die attach. Nearly all semiconductor chips are bonded to some type of substrate in an electronic package. Note: for those of you who are new to electronics, the term “packaging” refers to the materials used ... [Click to Continue...]

Have a Great Memorial Day Weekend

Happy Memorial Day Have a safe and relaxing Memorial Day Weekend and take some time to remember all those who have served our country. Special recognition to my late father, Captain Douglas Gotro, US Army, who was a Korean War veteran. I will be at the Electronic Components and Technology Conference (ECTC) next week. I will be presenting my short course on "Polymers ... [Click to Continue...]

Katherine Johnson: The Girl Who Loved to Count

I was on vacation last week and on the plane back to Orange County, I watched the movie "Hidden Figures" the story of the black female "computers" at NASA Langley in the early days of the space program. First of all, it was a great movie and a true story. Secondly, I was surprised I didn't know about the history of the legendary African American female computers. During the ... [Click to Continue...]