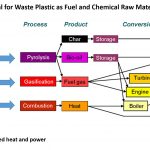

Guest Post by Dr. Robert (Bob) Humphreys In previous posts, we have discussed some of the trends in packaging that complicate the lives of the waste plastic recycling industry. Only 9.4% of the plastic in municipal solid waste (MSW) was recycled in 2014, based on data from the EPA (ref. 1), leaving about 30 million tons of waste plastic in MSW that is either landfilled or ... [Click to Continue...]

Recycle and Disposal of Plastic Food Packaging Waste 10: Thermal Technologies

Guest Post by Dr. Robert (Bob) Humphreys In the previous nine posts on plastic recycling and disposal, we focused on two approaches that require sorting: plastic composting; and separation of plastics that have commercial value in reuse. As we have seen, these methods do not provide a comprehensive solution to the waste plastic problem now and are unlikely to do so in the ... [Click to Continue...]

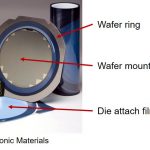

Polymers in Electronics Part Thirteen: Die Attach Adhesives Part 6

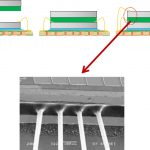

Source: Henkel The last post described the dicing die attach film (DDAF) approach used in multiple die stacking. This post will discuss the application of DDAF and some of the interesting aspects of using the “bundled” die attach film on the dicing tape. In Figure 1, the die attach and stacking process is shown for a two-die stack. The process begins with the placement of ... [Click to Continue...]

Polymers in Electronics Part Twelve: Die Attach Adhesives Part 5

I trust everyone had a nice Fourth of July holiday and had some time to relax with family and friends. We pick-up in this post with more information on film die attach. As was discussed previously, the requirement for uniform, thin bondlines drives the die attach design. Dicing Die Attach Film (DDAF) is the most common type of die attach film used in die stacking. The DDAF ... [Click to Continue...]

Happy Fourth of July

Summer time is a great time to take some time off and enjoy your family and friends. Have a safe and happy Fourth of July ... [Click to Continue...]