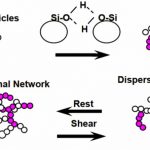

The last post introduced the concept of using fumed silica as a rheology modifier to tailor the dispensing of many types of adhesives used in electronic applications. In the image in the top right in the figure above shows a die attach adhesives dispensed on a PBGA substrate. After dispensing, the adhesives retain the “snowflake” or “asterisk” dispensing pattern. The ... [Click to Continue...]

Polymers in Electronic Packaging: Rheological Measurements, Part 7

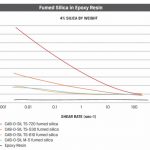

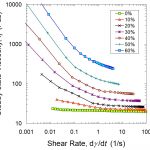

The last post described how to measure the viscosity-shear rate relationship using either a cone-and-plate or a parallel plate rheometer using a shear rate sweep. An example is shown above. This post covers how the viscosity profile influences the dispensing process and provides a short introduction to viscosity modifiers used to control the shear thinning and yield ... [Click to Continue...]

Polymers in Electronic Packaging: Rheological Measurements, Part 6

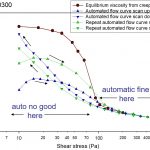

The last post described some of the potential pitfalls of the controlled stress measurements. Controlled stress measurements are good if you require a precise yield point measurement. An example would be if you were designing the yield point for a particular dispensing application. The point-to-point creep test would allow the yield point to be measured accurately. If on ... [Click to Continue...]

Happy Fourth of July

Have a Safe and Happy Fourth of July Thank you to all of my loyal readers. Polymer Innovation Blog hit a milestone in June with over 2,000 visitors in one week! I will be back next Monday, July 9 with more on rheology in electronic packaging. ... [Click to Continue...]

Polymers in Electronic Packaging: Rheological Measurements, Part 5

The last post described the controlled stress experiment. In the image above, a stress was applied to the sample and the deformation as a function of time (strain-rate) was measured at steady state. There are two measurement modes for controlled stress curves: Manual: a series of creep measurements (which was used above) Automatic: Flow or viscometry mode in a ... [Click to Continue...]